Senior Design Team Develops Showcase Cart for Nitroset

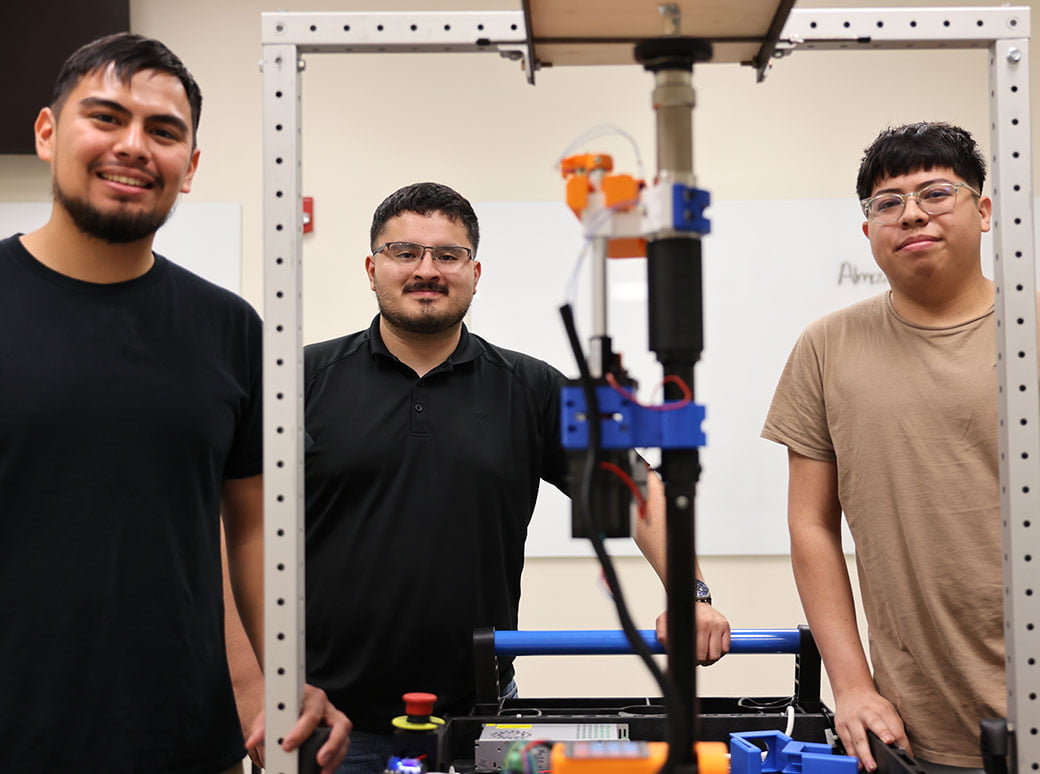

Josh Nevarez and teammates Victor Urena, Yoni Arias, Fatima Alaredhi, and Jose De la Torre worked with Houston-based Nitroset, which makes a solid propellant fastening system which uses the energy of its own solid propellant to drive fasteners into concrete rather than using traditional primer and gunpowder.

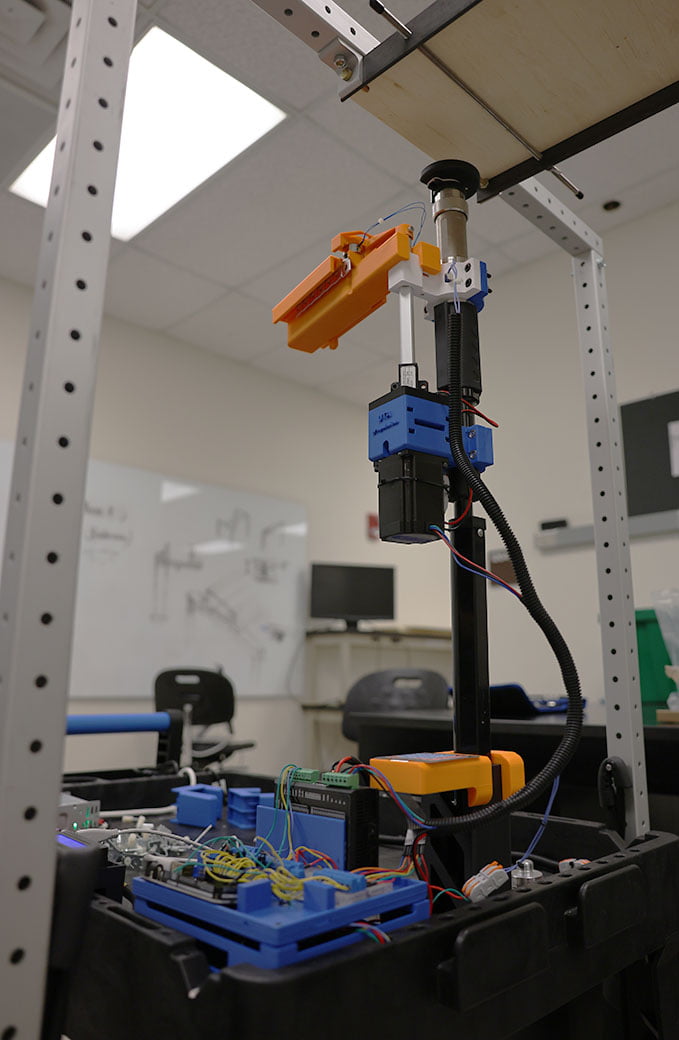

The company asked the team to automate one of the company’s standard utility carts to move, fire and reload the fastening tool. With materials provided by Nitroset and support from faculty advisor Raul Fernandez, the team fulfilled those objectives.

Nevarez and his team developed a portable demonstration piece for Nitroset to use at trade shows, highlighting one of the company’s fastening tools. Nitroset customers typically use the tool in overhead applications such as fastening wires to ceilings to hold tile framing.

“Our Design for Manufacturing class really helped with this project. Because of that class, we knew how to get our sketches approved, how to model and run simulations in CAD for our final concept, how to create the final design of the parts we made in the UTA machine shop, and then working to assemble the machinery,” Nevarez said.

“Nitroset liked our design, and they want to take it back and continue to work on it. Eventually, they want to make it autonomous for use in a work environment. They’ll look at it and decide how it will work best for their customers.”

The cart moves back and forth with a motorized wheel. It can hold eight Nitroset utility clips and automatically fire and reload them into a wooden surface. To enhance the demonstration experience, the team also developed a simulated ceiling assembled at eye level for easy viewing during operation. The tool, mounted on the cart, can fire the utility clips into a wooden plank.

The cart is equipped with a keypad interface, allowing Nitroset to initiate operation cycles easily. Each cycle can fire 2-4 utility clips, with an average runtime of approximately two minutes.

“I did the programming and coding on an Arduino. It allows the operator to assign how much the cart moves back and forth and how many stops it makes. One of the things I like about coding is making an idea work in reality,” Arias said.

Beyond the experience working with an industry sponsor, the team gained valuable insight into what it will be like when they enter the workforce as engineers.

“We’re going to be design engineers, so it’s important to be able to take a concept through the design stage to a final product. This was a good example of giving a group of people a project and working together to get it done,” Urena said.